TAC provide all processes of setting up and taking down oil drilling equipment, respectively.

Installation typically involves setting up a drilling rig, which is a complex system of machinery and equipment used to drill for oil or gas. The process may involve setting up the drill bit, running the drill string, and establishing the necessary connections and controls to safely operate the equipment. This may require the use of specialized crews and equipment, including cranes, trucks, and other heavy machinery.

Deinstallation, on the other hand, involves the dismantling and removal of the drilling equipment once the drilling operation is complete. This can involve disconnecting the drill string, dismantling the rig, and removing all associated equipment and materials from the drilling site. The process may also involve restoring the site to its original condition and addressing any environmental impacts that may have resulted from the drilling operation.

Both installation and deinstallation are critical processes in the oil services industry, as they help to ensure the safe and efficient extraction of oil and gas resources. Properly executed installation and deinstallation procedures can help to minimize the risk of accidents and environmental damage, while also ensuring that drilling operations are conducted in compliance with regulatory requirements.

Preventive maintenance and corrective maintenance are both crucial aspects of maintaining equipment and infrastructure in the oil services industry. Here’s an overview of what TAC offer:

Preventive maintenance: This type of maintenance involves performing regular checks, inspections, and servicing on equipment to prevent breakdowns and ensure optimal performance. The goal of preventive maintenance is to identify potential problems before they occur and address them proactively.

Examples of preventive maintenance in the oil services industry might include:

Regularly inspecting drilling rigs and equipment to ensure they are in good working order and replacing any worn or damaged parts.

Conducting regular oil and fluid changes in equipment to keep it running smoothly and prevent engine damage.

Performing regular safety checks and training sessions for workers to ensure they are using equipment correctly and safely.Corrective maintenance: This type of maintenance involves fixing equipment after it has broken down or malfunctioned. The goal of corrective maintenance is to restore equipment to its normal operating condition as quickly as possible.

Examples of corrective maintenance in the oil services industry might include:

Repairing drilling rigs or equipment that have experienced a breakdown or malfunction.

Conducting emergency repairs to pipelines or other infrastructure to prevent spills or leaks.

Replacing parts or components that have failed or become damaged beyond repair.

TAC provide the process used to clean, strip, or smooth surfaces by blasting them with a high-velocity stream of abrasive material. Sandblasting services are typically used in industries such as construction, manufacturing, and automotive to remove rust, paint, or other surface contaminants from metal or concrete surfaces.

Sandblasting can be done using a variety of abrasive materials, including sand, glass beads, aluminum oxide, and garnet. The type of abrasive used will depend on the surface being treated and the desired finish.

Technical coatings are widely used in the oil and gas industry to protect equipment and infrastructure from the harsh environments encountered during exploration, drilling, production, and transportation of oil and gas.

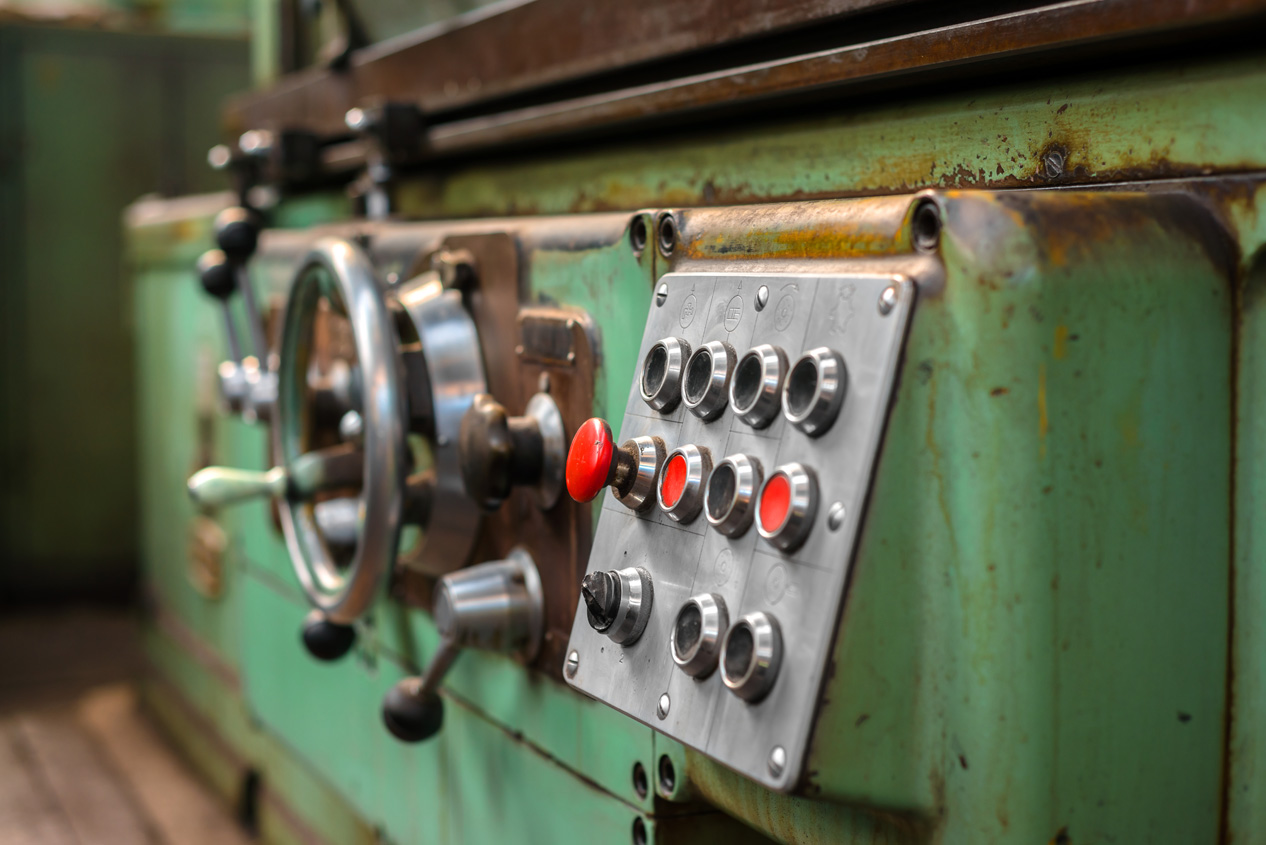

PLC programming (Programmable Logic Controller programming) is the process of creating software instructions that control the behavior of a PLC, a specialized computer designed to control industrial processes and machines. PLC programming involves using specialized software tools to create programs that implement specific control functions, such as turning motors on and off, controlling temperature, and monitoring inputs from sensors.

TAC PLC programming typically involves the following steps:

Identify the control requirements: This involves determining the specific control functions that the PLC needs to perform, such as turning motors on and off, controlling temperature, or monitoring inputs from sensors.

Develop the program: This involves selecting the appropriate programming language and creating the software instructions that will control the PLC.

Test the program: This involves running the program in a simulated environment to ensure that it functions correctly and meets the control requirements.

Download the program: Once the program has been tested and verified, it is downloaded to the PLC’s memory.

Monitor and adjust the program: Once the program is running, it is monitored for errors or anomalies, and adjustments are made as needed to ensure that the control functions are operating correctly.

Reliability engineering is a field of engineering that focuses on ensuring that systems and products are reliable, efficient, and safe for use. It is concerned with the design, development, testing, and maintenance of products and systems to ensure that they meet the requirements for reliability, availability, and maintainability (RAM).

TAC Electrical engineers play a critical role in the design, development, and implementation of automation panels. They are responsible for selecting the appropriate components, designing the electrical circuits, and ensuring that the panel meets the required specifications and standards. They also need to consider factors such as power consumption, electrical safety, and electromagnetic compatibility (EMC) when designing automation panels.

Logistic services play a crucial role in the oil and gas industry as they are responsible for the transportation and delivery of various materials, equipment, and supplies required for exploration, drilling, and production operations. TAC logistics services required in the oil and gas industry can be broadly categorized into three types: upstream, midstream, and downstream logistics.

Upstream logistics involves the transportation of equipment and supplies required for exploration and drilling operations, such as drilling rigs, pipes, chemicals, and personnel. These logistics services also include the transportation of crude oil and natural gas from the wellsite to the processing facilities.

Midstream logistics involves the transportation of crude oil and natural gas from the production site to the refineries or processing facilities. This type of logistics also involves the transportation of refined petroleum products to storage facilities or distribution centers.

Downstream logistics involves the transportation of petroleum products from refineries and storage facilities to retail outlets and end-users. This type of logistics also includes the transportation of by-products and waste materials generated during the refining and distribution process.

In addition to transportation services, logistic service providers in the oil and gas industry also provide other services such as warehousing, inventory management, and customs clearance. These services ensure that the right equipment and supplies are delivered to the right location at the right time, which is essential for the smooth functioning of the oil and gas industry.

QA/QC (Quality Assurance/Quality Control) services are critical in ensuring the quality and safety of products and services in various industries, including construction, manufacturing, and oil and gas. In the oil and gas industry, QA/QC services are particularly important due to the high-risk nature of the operations involved.

The primary goal of TAC QA/QC services is to ensure that the products and services meet the specified requirements and standards. In the oil and gas industry, QA/QC services cover a wide range of activities, including inspection, testing, and certification of equipment and materials used in drilling, production, and transportation.

Some of the specific services provided by QA/QC companies in the oil and gas industry include:

Inspection and testing of equipment and materials: This includes testing of drilling equipment, pipelines, valves, and other components to ensure that they meet the required specifications and standards.

Non-destructive testing (NDT) services: This involves using techniques such as ultrasonic testing, magnetic particle testing, and radiography to detect defects in materials and equipment.

Welding inspection: This involves inspecting and testing of welding joints to ensure that they meet the required standards and specifications.

Quality management: This includes developing and implementing quality management systems to ensure that the products and services meet the required standards.

Training and certification: QA/QC companies provide training and certification programs for personnel involved in oil and gas operations to ensure that they have the necessary skills and knowledge to perform their duties safely and effectively.

Inspection services are an important part of the oil industry, as they help to ensure that oil production and processing facilities operate safely, efficiently, and in compliance with regulatory requirements. Inspection services in the oil industry cover a range of areas, including:

Asset integrity inspection: This involves inspecting oil production and processing equipment, such as pipelines, storage tanks, and offshore platforms, to ensure they are in good condition and capable of functioning safely and effectively.

Non-destructive testing: This involves using specialized equipment and techniques to inspect the internal and external surfaces of oil production and processing equipment, without damaging the equipment.

Corrosion inspection: This involves inspecting oil production and processing equipment for signs of corrosion, which can cause equipment failure and pose a safety risk.

Quality assurance and quality control: This involves inspecting oil production and processing facilities to ensure that they meet quality standards and comply with regulatory requirements.

Environmental inspection: This involves inspecting oil production and processing facilities for potential environmental hazards and ensuring compliance with environmental regulations.

Safety inspection: This involves inspecting oil production and processing facilities to ensure that they comply with safety regulations and that personnel are following proper safety procedures.

Oil inspection services are typically performed by specialized inspection companies, and the results of the inspections are documented in inspection reports. These reports may include recommendations for repairs or upgrades to equipment, as well as suggestions for improving safety and environmental performance.

TAC provide Petrol chemical services to a wide range of services that are offered to companies and organizations involved in the production, transportation, and distribution of petrol chemicals.

Turning and grinding services are two types of machining services used to create precision parts from raw materials. Turning involves the rotation of a workpiece while a cutting tool removes material to create a cylindrical shape. wheel to remove material from Grinding, on the other hand, uses an abrasive the surface of a workpiece to create a flat, smooth finish.

Turning services are commonly used to produce cylindrical components, such as shafts, pins, and tubes, and can be performed using both manual and automated equipment. Grinding services are used to create precise finishes on flat surfaces or to remove material from a workpiece that is difficult to machine using other methods.

Both turning and grinding services are typically offered by machining shops or specialized companies that have the necessary equipment and expertise to produce high-quality, precise parts. When selecting a turning or grinding service provider, it is important to consider factors such as the company’s experience, capabilities, and quality control processes to ensure that your parts are manufactured to your specifications.

Fabrication services refer to the process of creating or manufacturing a product or component from raw materials through cutting, welding, bending, machining, and other techniques. These services are typically offered by companies that specialize in metal fabrication or other types of material fabrication, such as plastics or composites.

Fabrication services may include custom design, prototyping, production, and assembly of finished products. They are commonly used in a variety of industries, including automotive, aerospace, construction, and manufacturing. Some examples of fabricated products include structural steel, sheet metal parts, machine components, and welded assemblies.